Introduction

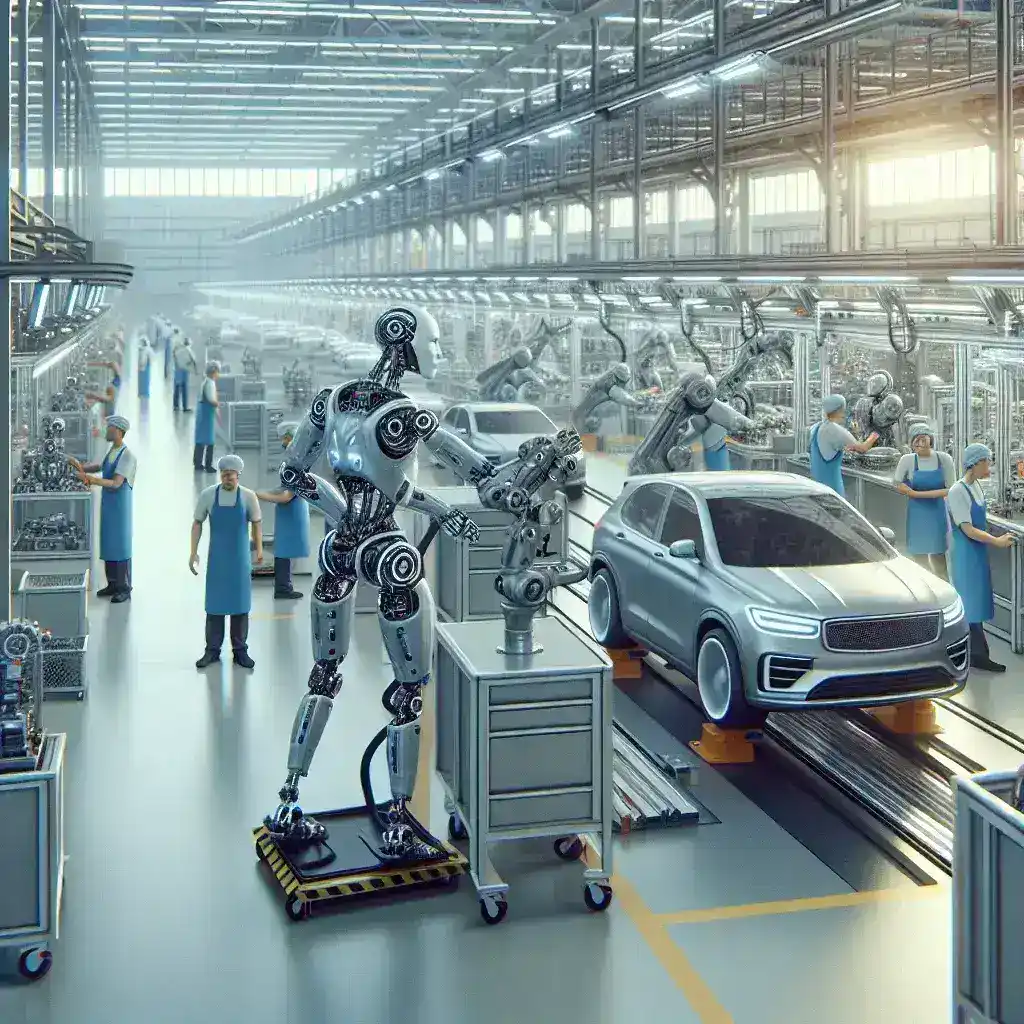

Tesla, the renowned electric vehicle manufacturer, is making headlines once again, this time for its groundbreaking initiative to pilot humanoid robots as factory workers at its Fremont plant. This bold move aims to revolutionize the manufacturing process, bringing efficiency and precision to the forefront of Tesla’s operations. As technology continues to evolve, the implications of integrating humanoid robots into the workforce are both exciting and complex.

The Vision Behind Humanoid Robots

Elon Musk, the CEO of Tesla, has long been an advocate for advanced technology in the production line. The introduction of humanoid robots aligns with his vision of creating an efficient and sustainable manufacturing ecosystem. These robots, known as Tesla Bot or Optimus, are designed to perform repetitive tasks, allowing human workers to focus on more complex and creative aspects of manufacturing.

Historical Context

The concept of robots in manufacturing is not new. The automotive industry has been utilizing robotic arms for decades to perform tasks such as welding and painting. However, the advent of humanoid robots represents a significant leap forward. Unlike traditional industrial robots, which are often confined to a specific set of functions, humanoid robots can navigate environments designed for humans, potentially transforming the way factories operate.

Features of Tesla’s Humanoid Robots

- Adaptability: Tesla’s humanoid robots are equipped with advanced AI and machine learning capabilities, enabling them to adapt to various tasks and improve their performance over time.

- Human-like Interaction: With a design that mimics human movement, these robots can work alongside human employees seamlessly, reducing the learning curve associated with training new machines.

- Cost Efficiency: By automating routine tasks, Tesla aims to reduce labor costs and increase production rates, ultimately benefiting the company’s bottom line.

Impacts on Employment

The introduction of humanoid robots raises important questions about the future of employment in the manufacturing sector. While some experts argue that robots could lead to job displacement, others believe that they will create new opportunities for skilled workers. The key lies in reskilling and upskilling the workforce to work alongside these advanced machines.

Pros of Integrating Humanoid Robots

- Increased Efficiency: Robots can operate continuously without breaks, leading to higher production output.

- Enhanced Precision: Human error is minimized, leading to improved product quality.

- Safety Improvements: By assigning dangerous tasks to robots, human workers are exposed to fewer risks, creating a safer work environment.

Cons of Integrating Humanoid Robots

- Job Displacement Concerns: The fear of losing jobs to automation remains a significant concern for many workers.

- High Initial Investment: The cost of developing and implementing humanoid robots can be significant, potentially impacting short-term profitability.

Future Predictions

The future of humanoid robots in manufacturing looks promising. As Tesla continues to refine its technology, we can expect to see more sophisticated robots that can handle a broader range of tasks. This evolution will likely lead to a shift in how manufacturing jobs are perceived, with an emphasis on collaboration between humans and machines.

Expert Opinions

Industry experts have differing views on the implications of humanoid robots in the manufacturing sector. Dr. Jane Smith, an AI researcher, states, “The integration of humanoid robots into factories will not only enhance efficiency but also redefine the roles of human workers. Training will be essential to ensure that employees can thrive in this new environment.” On the other hand, economist John Doe warns, “We must tread carefully. Rapid automation can lead to economic upheaval if we do not consider the social implications of job losses.”

Conclusion

Tesla’s pilot program for humanoid robots at the Fremont plant represents a significant step toward the future of manufacturing. As we observe the evolution of this technology, it is crucial to balance innovation with the potential impacts on the workforce. Embracing change while ensuring that workers are equipped for the future will be key to the successful integration of humanoid robots in the manufacturing landscape.